Hamilton’s Solution to Electronics Supply Chain Shortages

04.06.2025Global supply shortages in the electronics sector continue to pose challenges for companies. Nico Thöny, Head of the “ROB Embedded Systems” department at Hamilton Robotics, explains in an interview how Hamilton Robotics has created a solution to not only overcome these shortages through a flexible electronics platform, but also to make product development faster and more efficient.

Rinaldo Krättli: Nico, supply shortages repeatedly pose major challenges for many companies – especially when it comes to sourcing electronic components. How does Hamilton Robotics deal with this situation?

Nico Thöny: The supply of electronic components is indeed a challenge. Globally, there are recurring shortages, although the situation is currently far less severe than it was during the COVID-19 pandemic, when major market players bought up large quantities, making procurement much more difficult. During that time, we had to overcome additional hurdles – especially because our devices were in particularly high demand. Our liquid handlers were used for PCR testing, and the demand for testing capacity was enormous. If we hadn’t been able to deliver our devices at that time, it would have had dramatic consequences for testing capacity and, by extension, pandemic management. It was therefore especially important for us to find solutions to these shortages and to ensure that we could deliver our devices quickly and reliably.

RK: Hamilton has taken lessons from this and developed a solution that protects us from supply shortages – our own electronics platform. What specific advantages does it offer?

NT: Our new electronics platform enables significantly faster and more flexible development of new products, as well as optimization of existing technologies. Thanks to its modular design, we can selectively and efficiently assemble the right components to meet a wide variety of requirements. This allows us to deploy new applications for our liquid handlers even more quickly. Especially in times of uncertain supply chains, the platform gives us the necessary independence from external suppliers, allowing us to respond flexibly to market conditions and customer needs. This newly gained agility ensures that we can always guarantee the quality and availability of our devices – even under challenging conditions.

What is a electronics platform?

RK: What additional benefits does the new modular electronics platform offer?

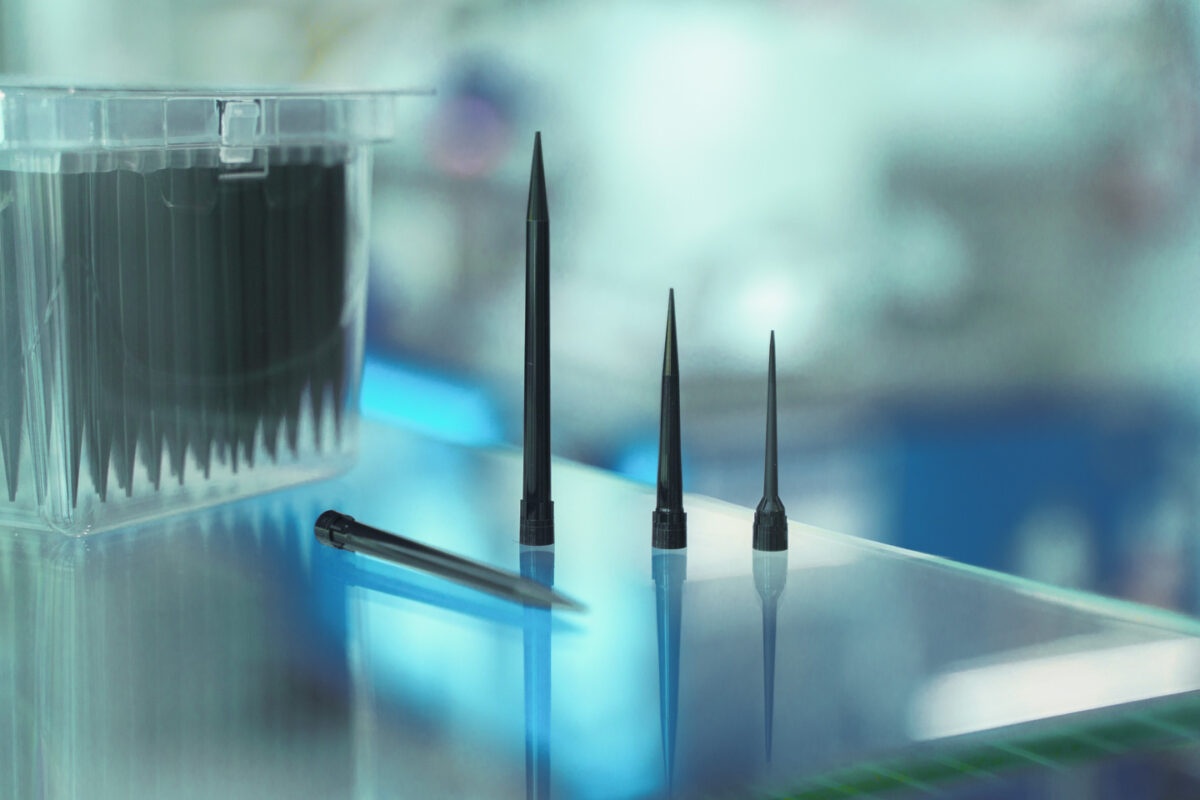

NT: One major advantage is the ability to collect and process far more data than before. With our new platform, we can monitor nearly all relevant process parameters in real time. This includes, for example, the system temperature, the pressure in the pipette tip, motor positions, and other parameters such as power consumption or drive speed. These data are collected, processed immediately, and made available in real time. As a result, we can continuously monitor the devices during operation, detect errors at an early stage, and optimize processes. This provides valuable insights not only for our developers and engineers, but also helps our customers make their own processes more transparent and efficient.

RK: How exactly do your customers benefit from real-time data processing?

NT: Real-time data processing offers our customers several advantages. On the one hand, they can monitor and control their processes with much greater precision. For example, they can determine whether the temperature remains within a specific range or whether the pressure becomes too high – both critical factors for the quality of sample handling. On the other hand, errors can be quickly identified and resolved, minimizing downtime. The transparent presentation of process data also enables better process validation and optimization. This is particularly important in regulated industries like the pharmaceutical and biotechnology sectors. Through continuous development and adaptation to the latest technological standards, we ensure that our products are always state-of-the-art – allowing us to provide the best possible solutions for our customers.