Smart Intralogistics at Hamilton

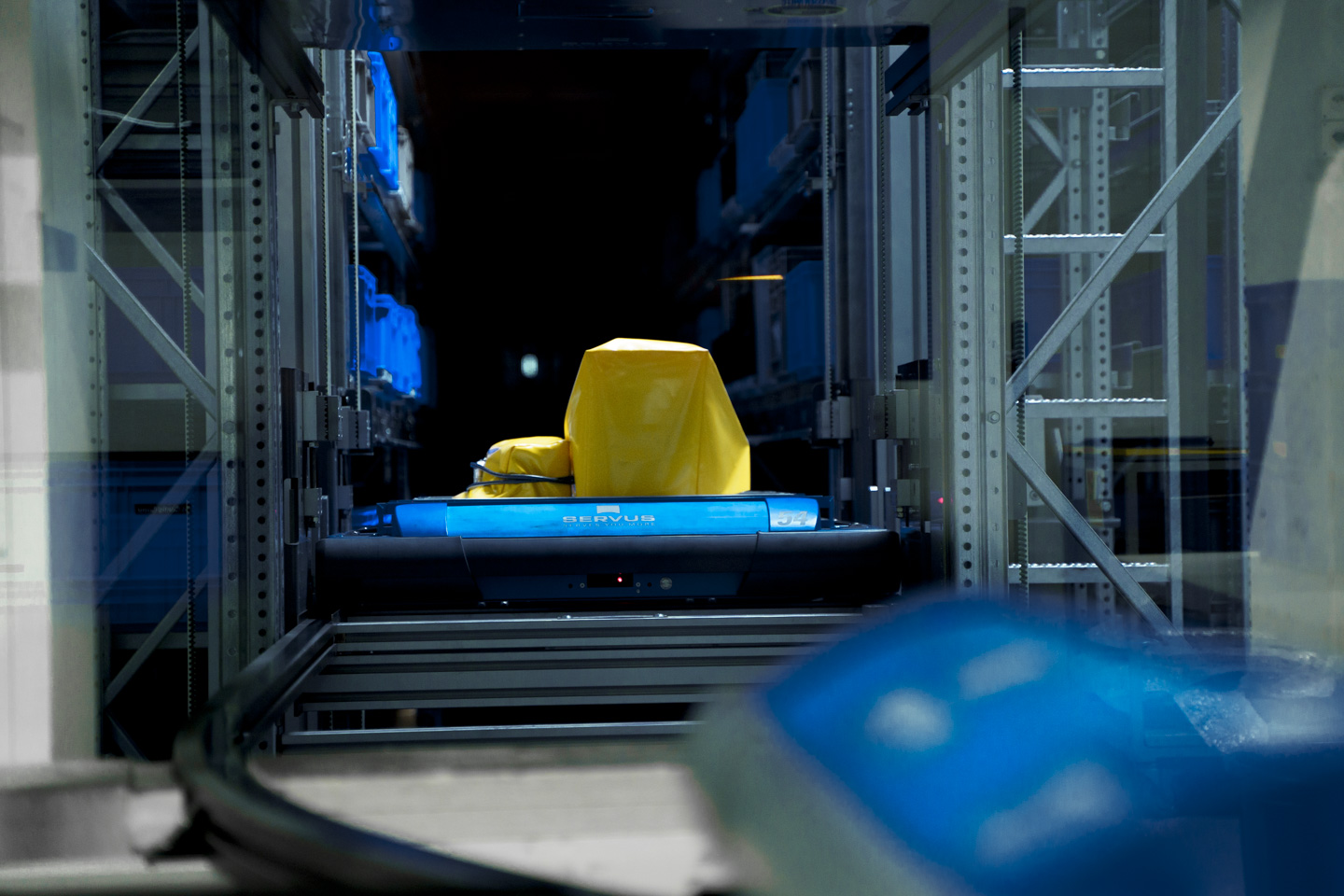

16.10.2025Hamilton’s facility in Domat/Ems runs on an advanced intralogistics system designed for maximum efficiency. It ensures a smooth material flow between the warehouse and the production areas.

The system includes a small parts warehouse with 27,000 storage locations, 65 transport robots, and a seven-kilometre rail network. It temporarily stores raw materials, semi-finished goods, and sales items. Each production department can store or retrieve materials directly within its area.

Automated Material Flow Throughout the Building

The warehouse connects to all production areas via the rail network. Transport routes run through the entire building and, thanks to elevators, across multiple floors. The robots pick up materials from the warehouse and deliver them straight to production. Return trips work the same way: employees can request a transport robot directly from their department. The robot then takes the material to the warehouse and stores it automatically.

Saving Time and Distance

The intelligent intralogistics system shortens walking distances and eliminates the need to search for materials. It always knows where every item is stored — streamlining processes and increasing productivity.

Facts & Figures

Transport Robots

- 65 transport robots

- 7 km rail network

- Payload: 35 kg

- Transports goods up to 60 × 40 cm

- Speed: 2 m/s

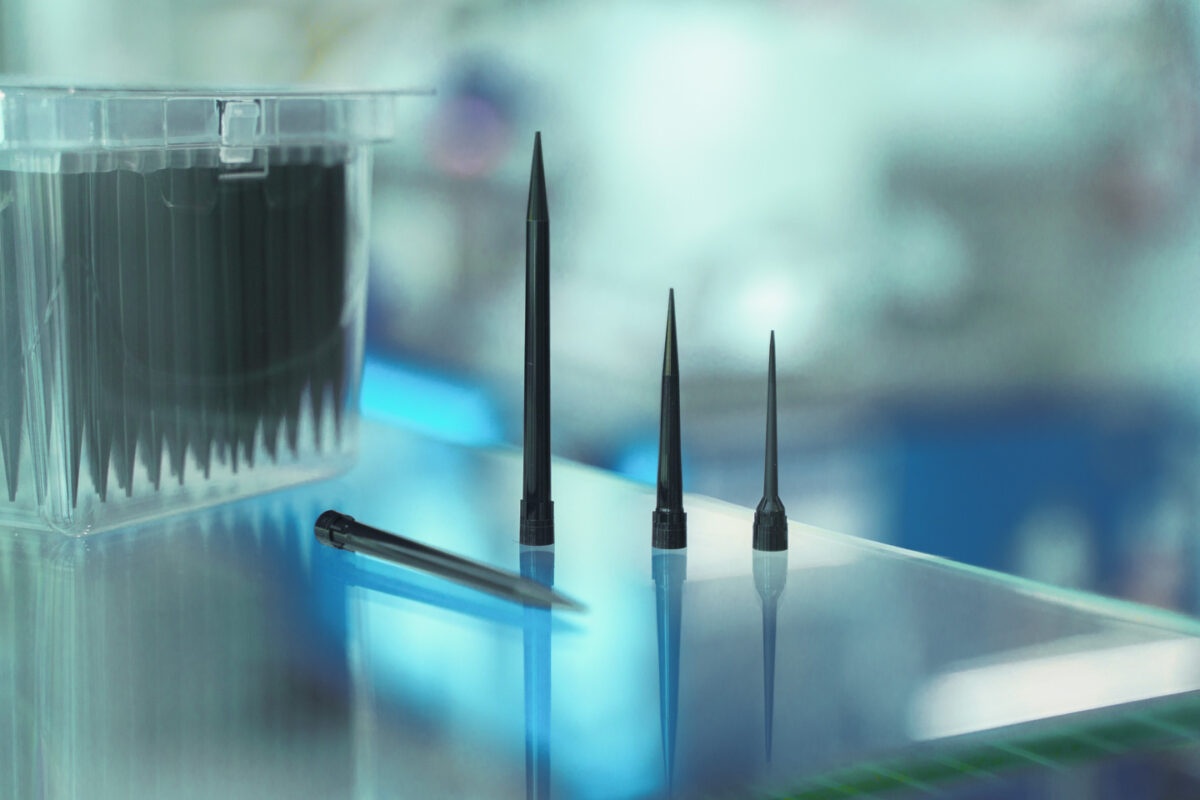

Automated Small Parts Warehouse

- 27,300 storage locations

- Dimensions: 36 m long, 16 m wide, 15 m high

- 7 aisles, 25 levels