Sustainably packed: less plastic, less CO2 – more environmental responsibility

26.06.2025Hamilton Bonaduz AG is firmly committed to the responsible use of natural resources. A recent example of this commitment is the switch to optimized packaging film in the intralogistics department – a measure that significantly reduces both plastic consumption and CO2 emissions.

Packaging more efficiently – with measurable impact

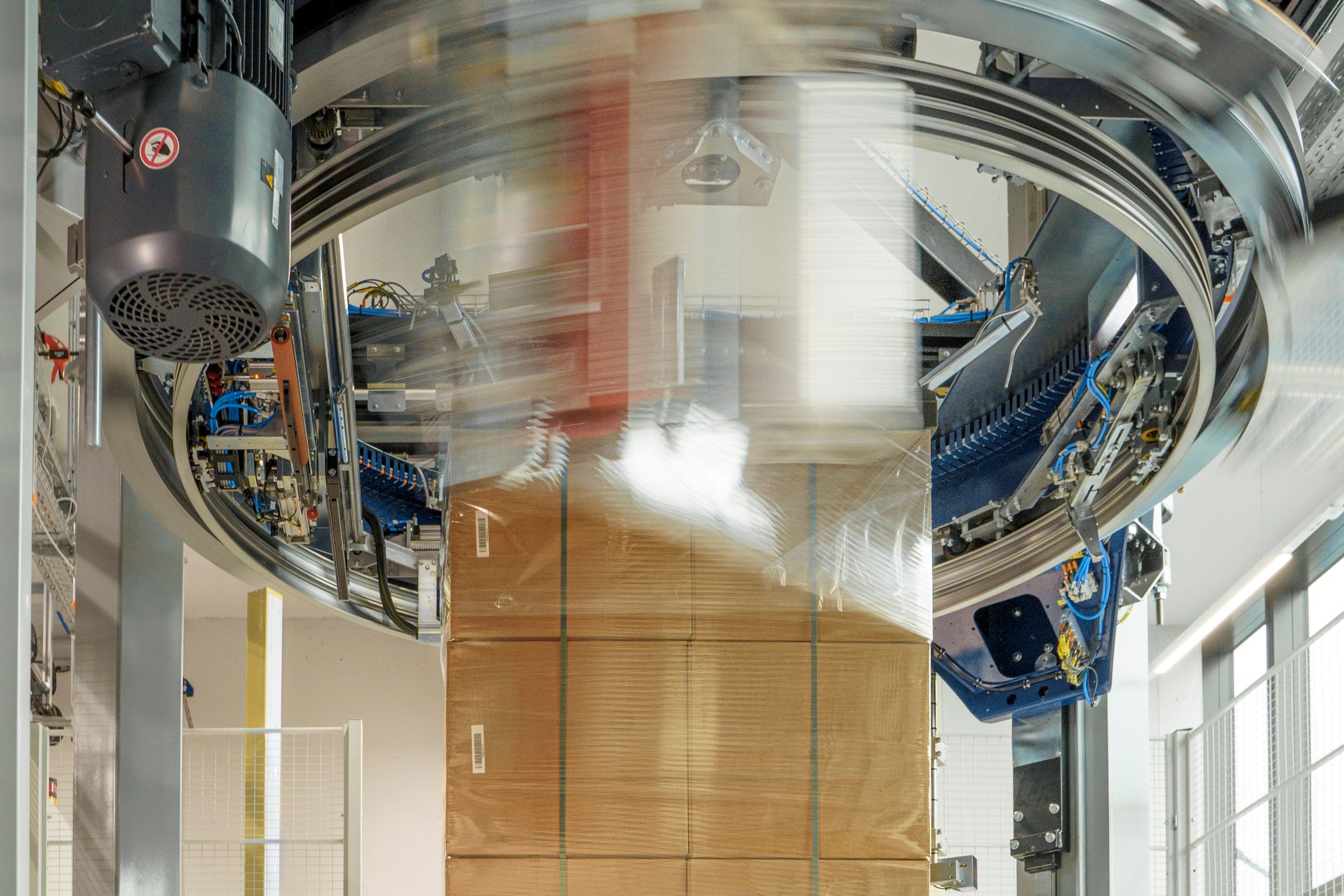

At our Domat/Ems site, modern conveyor systems and fully automated pallet wrappers ensure efficient shipping preparation. To secure products for transport, pallets are wrapped in plastic film – a critical step in the logistics chain.

Until recently, we used a 20-micrometer thick power stretch film made of Low-Density Polyethylene (LDPE). While it performed well in terms of tear resistance and flexibility, LDPE comes with relatively high weight – and a corresponding carbon footprint.

As part of our sustainability initiatives, we replaced the existing solution with a more efficient alternative: a 17-micrometer stretch film made of (Linear Low-Density Polyethylene (LLDPE). Thanks to its innovative material structure, the new film offers the same level of stability despite being thinner – and requires significantly less material.

This is how the pallet wrapper works

Tangible results at a glance:

- 1% less plastic

Annual film consumption has been reduced from 2,046 kg to approximately 1,226 kg – an annual saving of 820 kg plastic. - 6% fewer CO2 emissions

The new film not only uses less material but also lowers the carbon footprint by approximately 2,246 kg per year.

Small change, big impact

What may appear to be a minor technical adjustment actually highlights the potential of sustainable process optimization. This new stretch film is part of a broader series of targeted measures through which Hamilton intelligently combines environmental awareness with operational efficiency – even beyond the visible product landscape.

With innovation, responsibility, and a clear vision, we are shaping a more sustainable future – for medical technology and beyond.