Hamilton Increases On-Site Power Generation to Record Levels

12.09.2025The Domat/Ems site achieves a remarkable self-consumption rate of 89% – a milestone for sustainable industrial production in Switzerland.

The Domat/Ems site achieves a remarkable self-consumption rate of 89% – a milestone for sustainable industrial production in Switzerland.

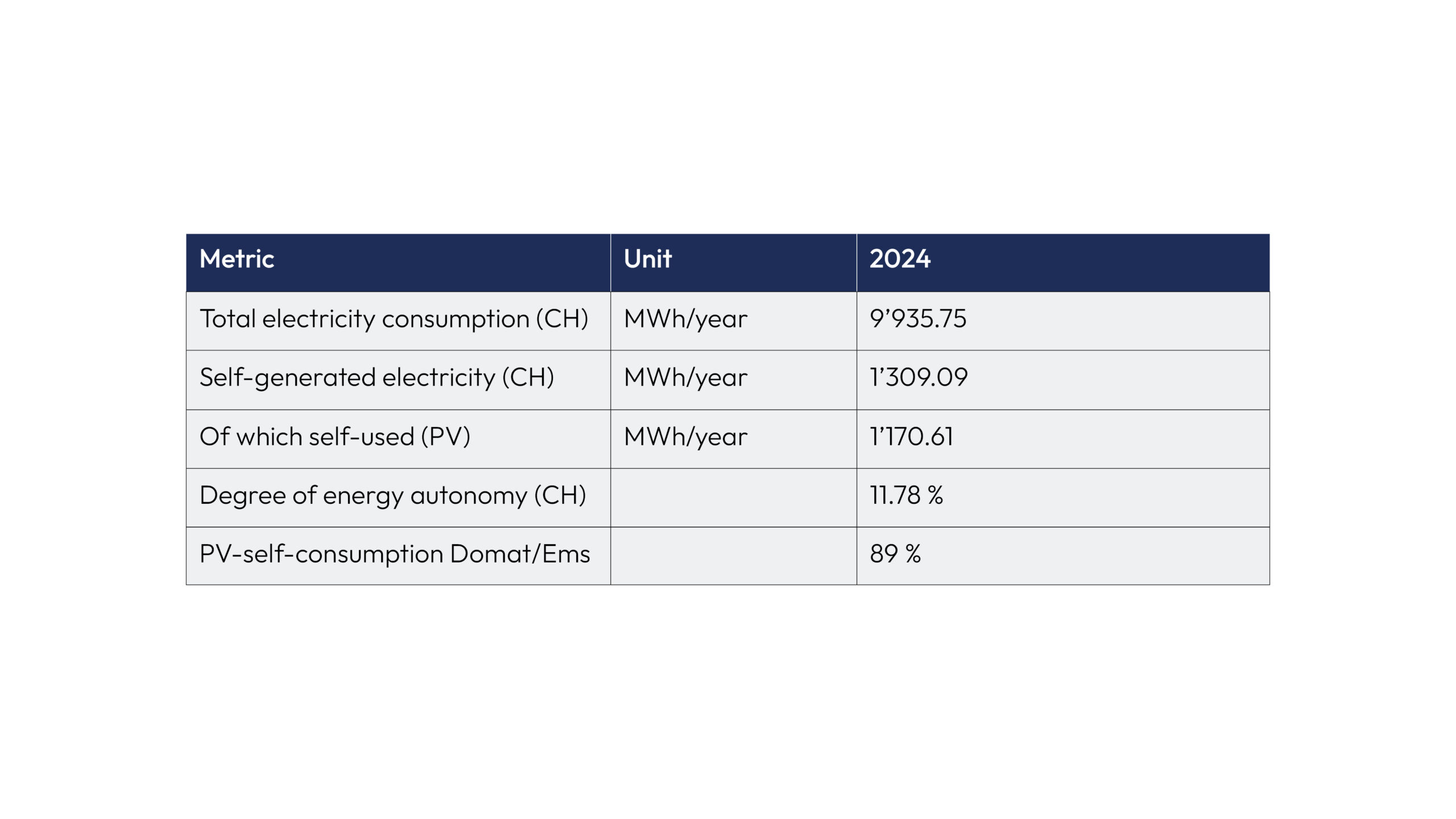

Hamilton’s Domat/Ems site, winner of the Swiss Solar Prize 2024, is a compelling example of how modern industrial manufacturing can be efficient, climate-friendly, and resource-conscious. In 2024, Hamilton’s Swiss sites in Bonaduz and Domat/Ems generated approximately 1,309,09 kWh of CO2-free solar power – an impressive 89% of which was consumed directly on-site. The remainder was fed into the national power grid.

Self-Generated Power as a Pillar of Energy Supply

The installed photovoltaic capacity at the two Swiss sites totals 2.283 MWp. The PV systems are architecturally integrated, covering roofs and façades with south-, east-, and west-facing panels. The electricity generated supplies the production facilities and covers a significant portion of the sites’ total electricity needs.

To put it in perspective: the electricity generated in 2024 would be enough to power 468* electric vehicles for 10,000 km per year – entirely CO2-free.

*Based on a conservative estimate of an energy consumption of 28 kWh per 100 kilometers, the electricity produced by Hamilton could power a total of 468 electric vehicles to each travel a distance of 10,000 kilometers

Domat/Ems Sets New Standards in Production

The Domat/Ems site stands out in particular as the largest industrial building in Switzerland certified to the Minergie-P standard – with additional certification under Minergie-A. These standards represent the highest levels of energy efficiency and the maximum use of renewable energy sources. The ambitious goal: to generate more energy than is consumed.

This is already being achieved today through a wide range of innovative solutions:

- Groundwater heat pumps provide environmentally friendly heating and cooling.

- Smart building automation ensures demand-driven control and optimization of all operations.

- Consistent heat and moisture recovery increases energy efficiency without compromising employee comfort.

- An electronic façade reduces heat input by automatically dimming in sunlight, while still offering an unobstructed view outside. This significantly reduces cooling needs during the summer.

A Model for the Future

Smart building design at Hamilton considers not only energy efficiency but also employee comfort and safety. The innovative construction of the Domat/Ems site enhances both efficiency and occupational safety while reducing emissions. The figures speak for themselves:

Through these structural and technological measures, Hamilton reaffirms its strong commitment to sustainability, innovation, and responsible business practices. The growing share of self-generated electricity is a key step toward a carbon-neutral industrial future.